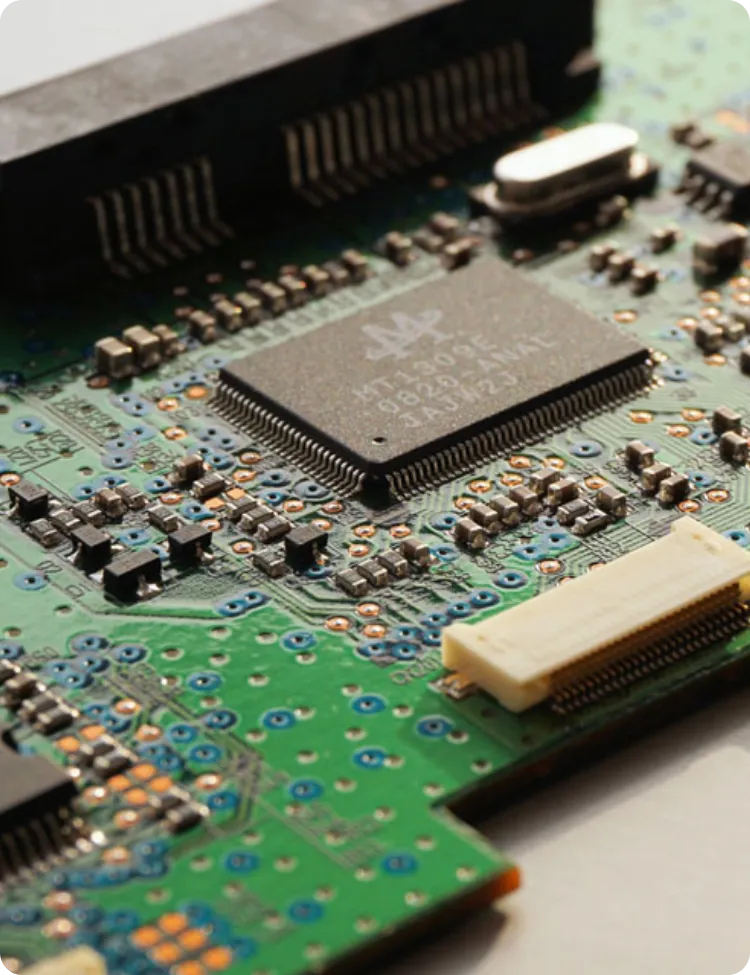

Printed Circuit Board Assembly Specialists for the Industrial Power Industry

Your trusted partner in industrial power management, controls, and energy-efficient solutions tailored to maximize operational productivity and sustainability.

About Us

Your Trusted Partner in Industrial PCB Assembly

At Acorn Assembly, we specialize in providing PCB assembly solutions tailored for the Industrial Controls and Power Industry. From precision prototypes to scalable production, we deliver reliable solutions that power essential equipment in industries like automation, energy management, power distribution, and renewable energy systems.

35+ Years of Industry Experience

Turnaround Time as Fast as 10 Days

ISO-9001-2015 Certified

Our Services

Prototype Assembly

Fast and precise prototyping for your industrial control systems.

Low-Volume Assembly

Tailored solutions for small-batch production in energy and automation.

Turn-Key Services

From sourcing components to final assembly, we handle it all.

Production Assembly

Efficient and consistent solutions for large-scale industrial production.

Prototype Assembly

Driving Innovation in Industrial Controls

At Acorn Assembly, we understand that the Industrial Controls/Power Industry demands high reliability and precision. Our prototype assembly services are tailored to meet these critical needs. Whether you're developing a next-generation motor controller or an advanced energy management system, we transform your innovative designs into reality with unmatched accuracy and care.

Why Choose Our Prototype Assembly Services?

Tailored Solutions: Optimized for industrial applications requiring robust and durable components.

High-Quality Standards: Exceptional attention to detail at every stage of assembly.

Timely Delivery: Your deadlines are our priority.

Let us help you take your project from concept to reality with seamless prototype assembly services.

Why Choose Acorn Assembly?

With decades of experience and a proven track record, Acorn Assembly has become a trusted partner for leading companies in the Industrial Controls/Power Industry. Here's why businesses rely on us:

Responsiveness You Can Rely On

We prioritize your success by maintaining open, transparent communication throughout the process. You'll always be informed about your order status, ensuring peace of mind.

Uncompromising Quality

We leverage cutting-edge equipment and experienced technicians to deliver assemblies that meet or exceed the rigorous requirements of industrial applications. From high-power motor drives to precision control systems, quality is always our top priority.

Specialized Expertise

We bring in-depth knowledge of power systems, industrial automation, and renewable energy solutions, ensuring your PCB assemblies are designed to excel in demanding environments.

Production Assembly

Scalable Solutions for Industrial Applications

Our production assembly services are tailored to meet the unique challenges of the Industrial Controls/Power Industry. Whether you need small-batch runs for specialized equipment or large-scale production for power systems, our skilled team ensures your assemblies are efficient, consistent, and reliable.

What Sets Our Production Assembly Apart?

Scalable Solutions: Designed to handle projects of any size, from niche controllers to large-scale power modules.

Durability and Precision: Assemblies built to withstand harsh industrial environments.

Streamlined Efficiency: Delivering on time, every time, without compromising on excellence.

Partner with Acorn Assembly to keep your production process running smoothly and your customers satisfied.

Industries We Serve

Industrial Automation

Advanced control systems for optimized manufacturing.

Energy Management

PCB assemblies for energy monitoring and distribution systems.

Renewable Energy

Reliable solutions for solar, wind, and other sustainable energy sources.

Power Distribution

Precision assemblies for transformers, inverters, and power grids.

Motor Control Systems

Scalable solutions for high-performance motor drives.

TESTIMONIALS

What others are saying

"5 Stars!"

"Acorn Assembly has been a big part of our success; they have consistently built quality products for us for years. Their customer service is always quick with an answer. 5 Stars!"

- Azadeh, Rail Logic

"Unmatched Excellence"

"Acorn Assembly has been one of our greatest partners over 2024, they always achieve whatever they commit to do, and excel at manufacturing and quality. Having some of our more complex boards being built over here, is giving me confidence to continue strengthening our partnership over 2025 and beyond."

- Eliseo, MacroFab

FAQs

PCB Assembly FAQS

What information do you need to quote a PCB Assembly project?

To provide a quote for a PCB Assembly project, we typically need the following information: Gerber files for the PCB design, a Bill of Materials (BOM) with component details, assembly drawings, a pic-n-place file (Centroid if available), and any special requirements or instructions you might have for your assembly.

Can you handle RoHS-compliant PCB assembly?

Yes, we absolutely can. We are fully equipped to manage the RoHS (Restriction of Hazardous Substances) compliant PCB assembly process. This means we ensure that the assembly process and all components used comply with the regulations set out by RoHS, which limits the use of specific hazardous materials in electronic equipment.

We understand the importance of environmental responsibility in electronics manufacturing and are committed to meeting the highest safety and sustainability standards. Therefore, we can confidently offer our customers RoHS-compliant PCB assembly services without compromising on quality or performance. If you have specific requirements or need further information regarding our RoHS-compliant processes, please do not hesitate to get in touch with us.

What types of certifications or registrations do you have?

We take great pride in the various certifications and memberships that affirm our commitment to delivering high-quality, reliable PCB assembly services. Our company is:

• ISO 9001:2015 certified, indicating our dedication to quality management and continuous improvement.

• ITAR registered, showcasing our ability to handle projects related to defense and military applications.

• UL Registered, verifying our products’ safety and compliance with established industry standards.

• IPC member, applying standards that increase our quality of assembly, as well as keeping up with the best practices in the electronics industry.

• RoHS-compliant, underscoring our commitment to environmental responsibility and the reduction of hazardous substances when our customers require that compliance.

We strive to maintain these qualifications to provide the highest level of service to our customers, ensuring peace of mind with every project.

What type of quality checks do you perform during and after the assembly process?

The quality control process typically involves visual inspection, Automated Optical Inspection (AOI), and X-ray inspection. In addition, you can request, and we can provide additional post-assembly testing, including Flying Probe Testing, In-Circuit Test (ICT), or Functional Circuit Test (FCT), depending on the complexity of the boards and your requirements.

Do you offer turnkey PCB assembly services?

Yes, we are proud to offer comprehensive turnkey PCB assembly services. This means we handle the entire process from start to finish, allowing you to place a single order and receive fully assembled boards. Our turnkey service includes PCB fabrication, component procurement, assembly, quality control, and testing.

What if I have my own components or boards for the assembly?

Absolutely, we accommodate that scenario. We understand that our customers sometimes have specific, potentially hard-to-source electronic components or pre-manufactured boards that they wish to use. We are fully prepared to integrate these into the assembly process. Our objective is to offer maximum flexibility to meet your unique needs and ensure the final product aligns with your expectations. Please ensure to communicate this requirement at the project’s outset so we can best accommodate your needs.

Copyrights 2025 | Acorn Assembly | Privacy Policy | Terms & Conditions